OUR MONO-PP SOLUTIONS

Making the packaging world more sustainable

OUR MONO-PP SOLUTIONS

Making the packaging world more sustainable

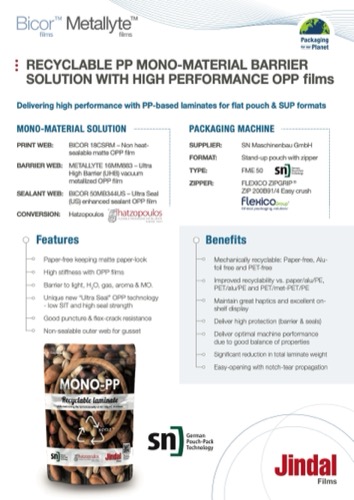

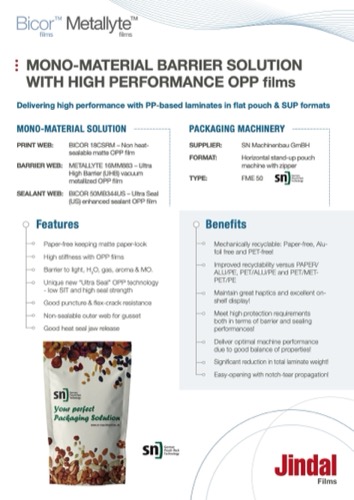

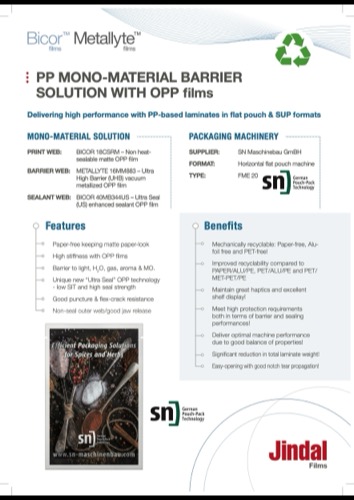

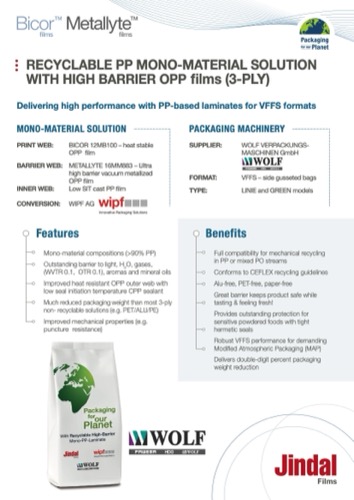

PP Mono-Material Solutions

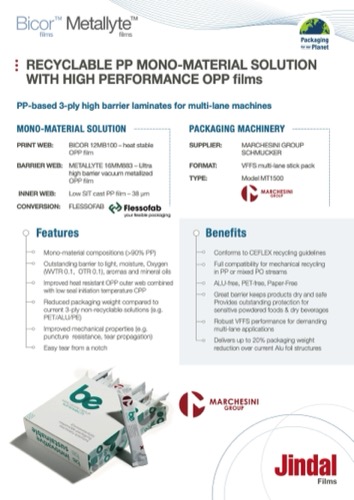

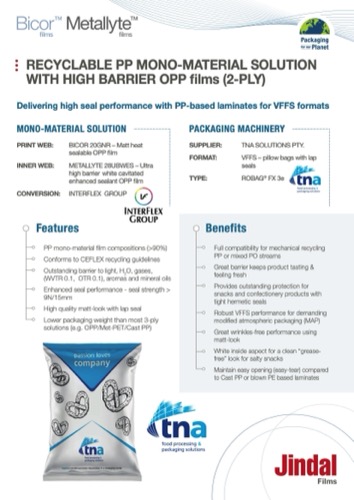

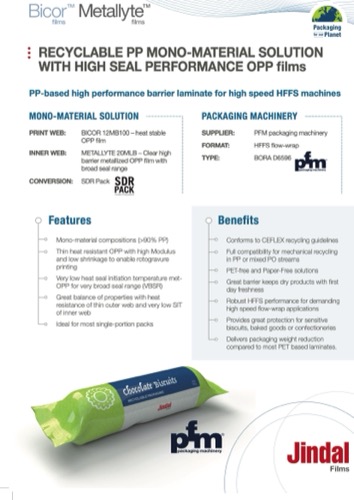

IMPROVED FLEXIBLE PACKAGING RECYCLING

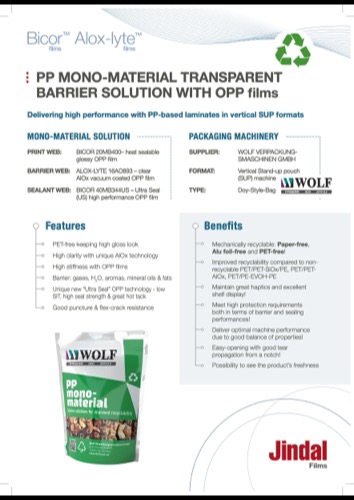

WITH MONO-MATERIAL SOLUTIONS USING OPP FILMS

PRINTABLE WEBS

Replace paper or PET with OPP using a broad range of features

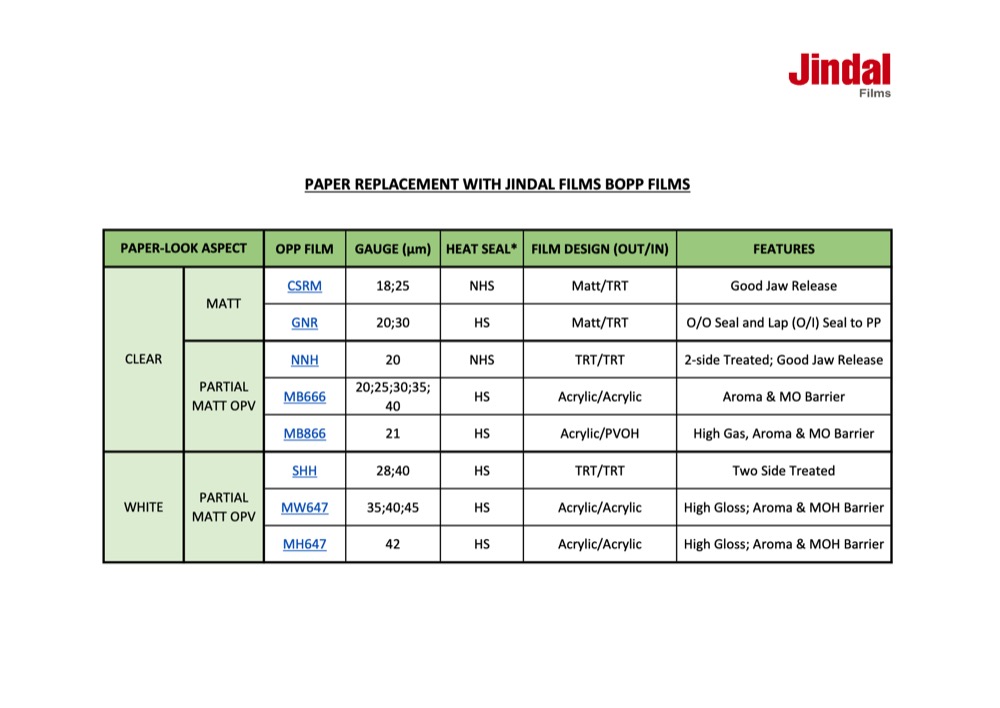

Some of the most demanding packaging formats and product segments are using paper, oriented PET films or other harder to recycle substrates in laminate forms. Papers and PET films are stiff, heat stable and tolerate high seal jaw temperatures allowing for a robust packaging operation.

To replace Paper or PET films, OPP films are available with a broad range of features. Commonly available in white or clear, matt or glossy, one or two-side processable, heat sealable or non-sealable, barrier or non-barrier formulations and usually compatible with most printing and lamination processes.

PAPER can be substituted either with OPPalyte™ white OPP films either glossy (SHH) or with reverse printed Bicor™ clear OPP films with a matt look (CSRM).

PAPER REPLACEMENT WITH BOPP FILMS

Footnotes: NHS = non heat sealable; HS = heat sealable; MO = barrier to mineral oils; * lap sealable to PP films;

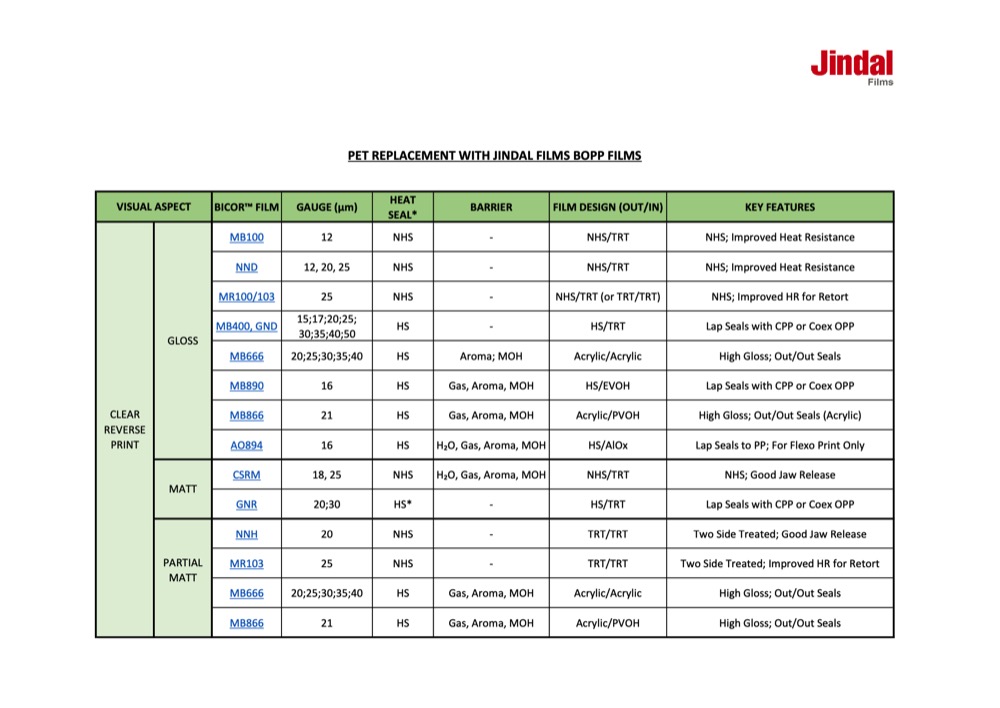

Glossy or matt PET films can be replaced with Bicor clear OPP films (Bicor™ MB100, NND, NNH, CSRM) to

deliver various functional features or visual aspects depending on the final use.

Optionally clear barrier OPP films (MB890, MB866, AO894) are also available in various gauges for two-ply applications using reverse printing. Alternatively, coated white barrier OPP films (MW647, MH647) provide outstanding glossy white aspect with excellent barriers to aroma and mineral oils.

PET REPLACEMENT WITH BOPP FILMS

Footnotes: NHS = non heat sealable; HS = heat sealable; MO = barrier to mineral oils; * lap sealable to PP films;

resistance OPP films for general outer web applications (Bicor™ MB100), or for more specific segments where extra heat processing is used (Bicor™ MR100) such as retort or sterilization.

BARRIER WEBS

Replace Alu Foil or vacuum coated PET with OPP barrier films

For sensitive products, many barrier laminates still use thin Aluminum foils or vacuum coated PET films (clear coated or metallized) that are non-recyclable when combined with printable outer web or sealable inner web polyolefin films. Outstanding moisture, gas, light and aroma barriers can be delivered with OPP films and usually results in improved mechanical properties such as puncture or flex-crack resistance.

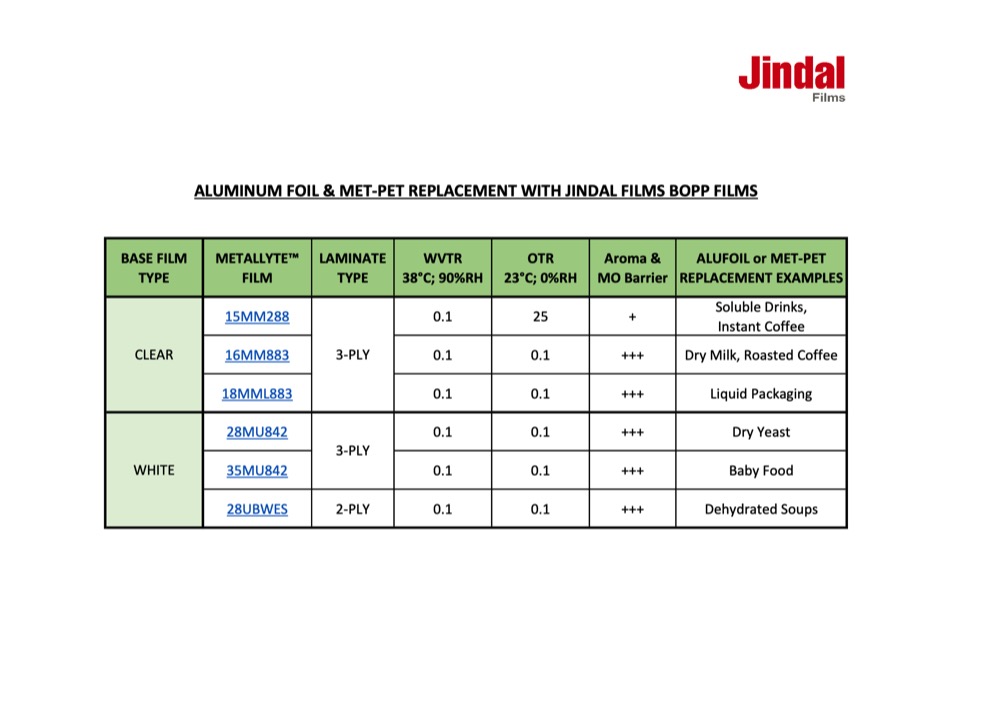

ALUMINUM FOIL & MET-PET REPLACEMENT WITH BOPP FILMS

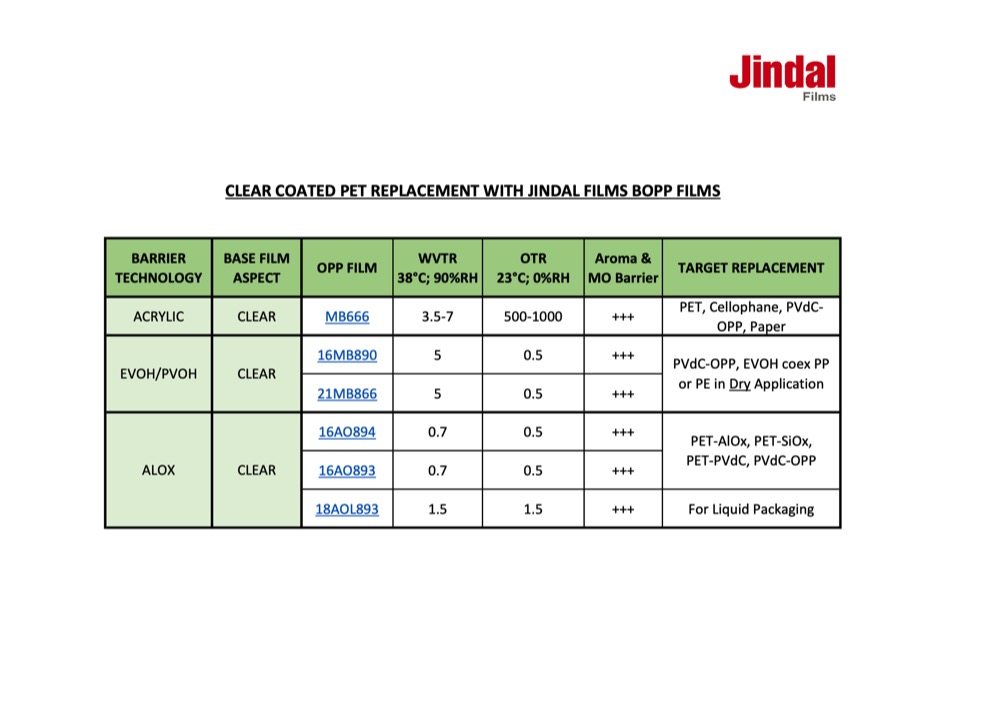

For transparent applications, Alox-Lyte™ films (AO894, AOL893, AO893) or Bicor™ coated films (MB866, MB890) are suitable to either replace SiOx or AlOx vacuum coated PET films or to shift thicker barrier layers (EVOH) from coextruded PE or PP sealants to the middle or outer webs of laminates and results in improved PP mono-material composition for better recyclability.

CLEAR COATED PET REPLACEMENT WITH BOPP FILMS

Footnotes: MO = barrier to mineral oils

Jindal Films is continuously improving its high barrier technologies with better tolerances as well as developing modified OPP films for more demanding applications such as for liquid packaging or for retort sterilized segments.

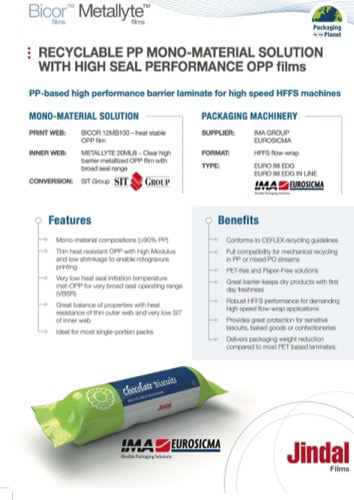

HEAT SEALANT WEBS

Replace PE films with enhanced seal performance OPP films

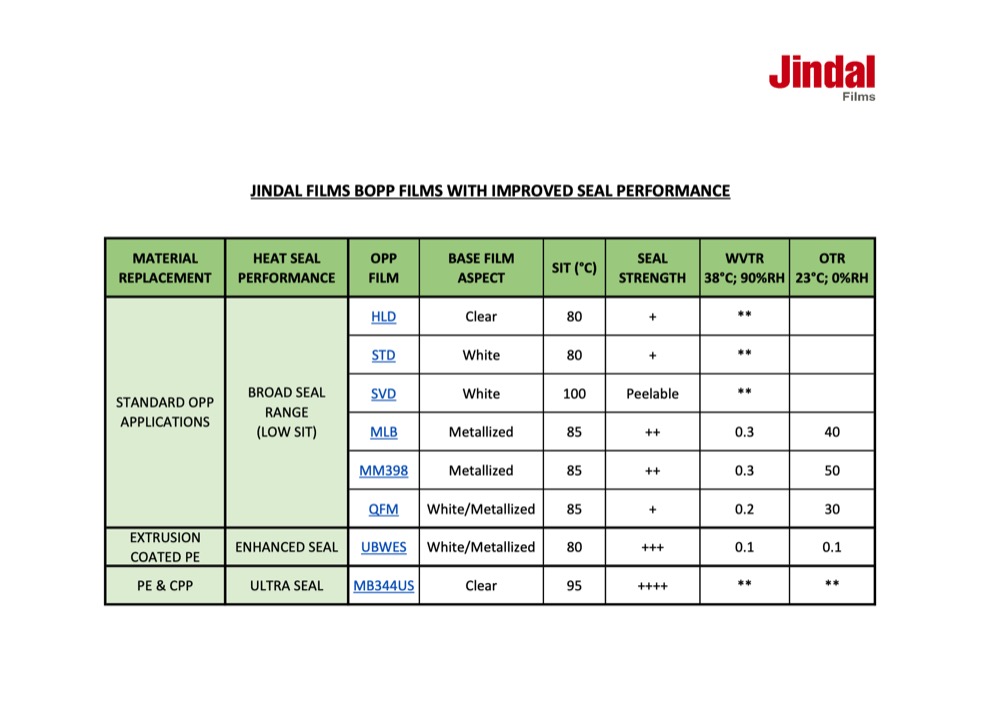

Most demanding packaging applications – such as for powdered products or those with MAP – use blown or cast polyethylene heat seal films that contribute to strong pack integrity. Cast PP or enhanced BOPP films can be used to shift the final laminate towards a PP mono-material composition, resulting in improved recyclability. OPP films provide enhanced mechanical properties (e.g. high stiffness, great puncture resistance) over most blown or cast films, to help to significantly down-gauge the sealant webs and provide additional features like easy tear propagation from a notch or from a crimp-seal.

Jindal Films has developed specific Bicor™ or Metallyte™ OPP films with higher seal performance to partially close the gap with PE sealants. The latest generation of Bicor™ Ultra Seal films (MB344US) delivers 6 times higher seal strength than most standard coex OPP films, with exceptional hot tack window and often with lower seal initiation temperatures (SIT) than most cast PP films.

OPP FILMS WITH IMPROVED SEAL PERFORMANCE

Footnotes: * There are different minimum seal strength thresholds for various technologies ** WVTR dependent on base film thickness;

In summary, PP mono-material solutions from Jindal Films provide numerous OPP film options – printable, barrier and heat sealable – to help brand-owners and converters launch their multi-material flexible packaging laminates on a journey towards a more sustainable future, feeding the PP recycling streams being progressively implemented across Europe.