RECYCLABLE MONO- MATERIAL BOPE PACKAGING

Creating the future together

ETHY-LYTE™

DESIGNED TO PERFORM & TO BE RECYCLED

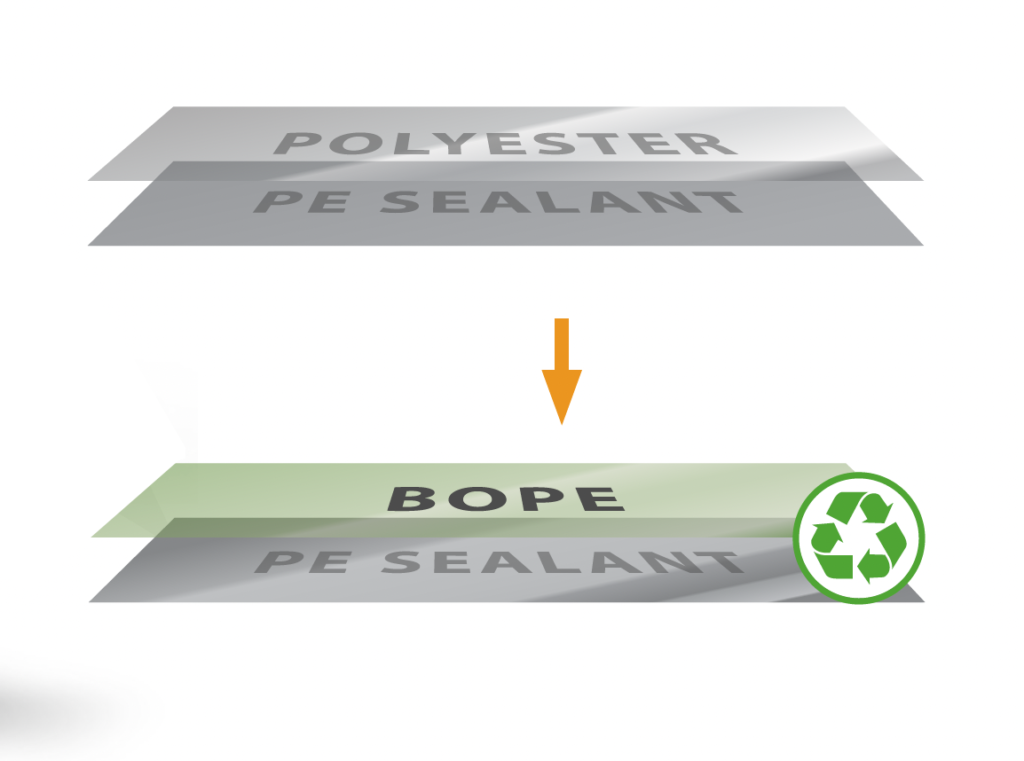

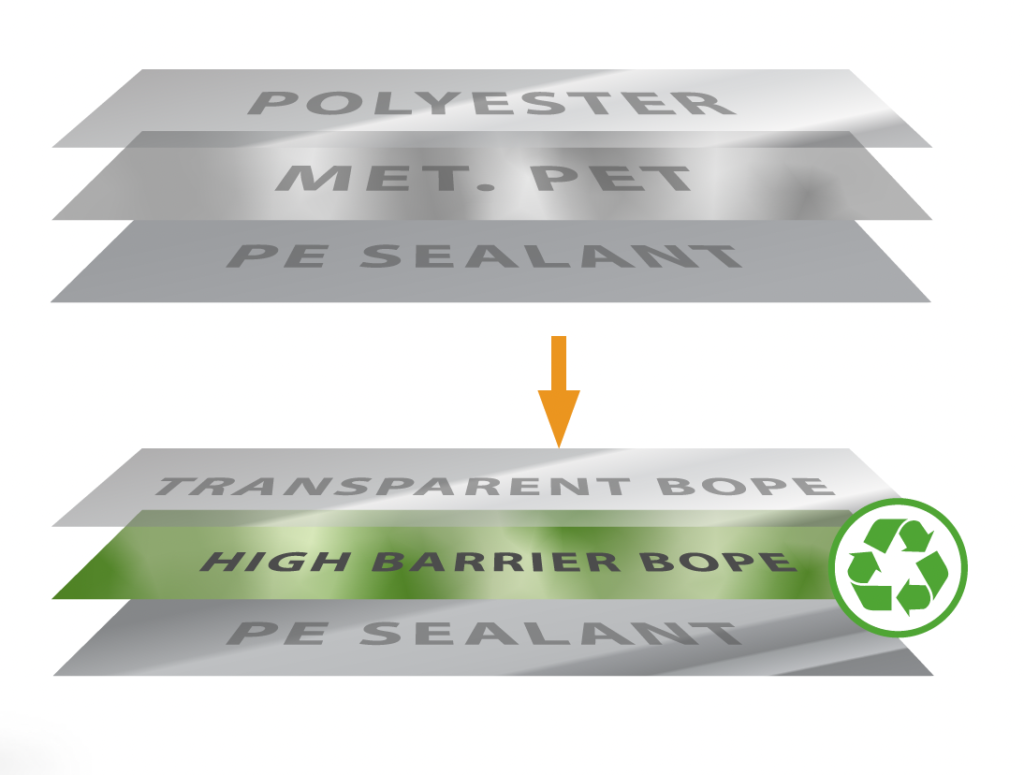

Jindal Films has introduced a range of high performance bi-oriented Polyethylene film, which can be used as a printing or high barrier lamination film for substituting non-recyclable components in PE laminates, like Polyester, Polyamide or Paper.

With Ethy-Lyte™ BOPE films it’s easy to generate recycle friendly Mono PE laminates which can be used for most applications in flexible packaging.

THE TECHNOLOGY BEHIND ETHY-LYTE™

The bi-axially orientation process combined with advanced PE resins provide homogeneous and mechanical stable BOPE films with excellent performance in converting and packaging processes. The high quality BOPE films also possess all characteristics for generating high barrier and ultra high barrier films, by using metallization and coating technology.

PRINTING & DESIGN SOLUTIONS

Broad feature range for high end print designs

Ethy-Lyte™ BOPE films are designed for best performance in printing:

Generating recycle friendly Mono PE laminates by replacing PET, OPA. OPP or Paper printing materials.

Ethy-Lyte™ printing films are following the latest design trends in flexible packaging. Ethy-Lyte™ provides suitable base films for several optical effects, like matt finish & paper look, matt-gloss designs.

HIGH BARRIER SOLUTIONS

Best protection for sensitive products

Ethy-Lyte™ barrier films are developed to substitute metallised Polyester films or Aluminium foil in mixed material laminates, to create fully recyclable Mono PE solutions. The films provide excellent oxygen and water vapour barrier as well as aroma protection.

Ethy-Lyte™ high barrier films can be used for duplex or triplex Mono PE high barrier larninates. Transparent high barrier printing film are used in 2 ply laminates with options for window prints. The high barrier metallized films are 2 side process able and can be used as a mid-layer in 3 ply laminates for challenging applications.

Replacing met. PET, Alu foil or extruded EVOH in laminates with PE sealing films

Mono PE high barrier solutions include well established PE sealing films and provide high seal integrity and seal strengths. It can be used for many challenging applications like coffee, nuts, powder products, fresh food, Pet food and others.

PACKAGING FORMATS

Suitable for all standard pack formats, like HFFS, VFFS, Stand Up Pouches, Lid Films, Premade Pouches & Bags up to 20kg

MARKET SEGMENTS

OUR SUSTAINABILITY APPROACH

PROVEN RECYCLABILITY OF ETHY-LYTE™ solutions

The Cyclos Institute verified the recyclabillty of all Ethy-Lyte™ films laminated with PE sealing films: triple AAA recyclabillty // excellent performance in mechanical recycling processes.

PRODUCT DATA SHEETS

You will find the technical data information for all available products in the dedicated product data sheets. Simply click below.

For more information, you can contact the Ethy-Lyte™ team via the following email address: Ethy-Lyte@jindalfilms.com