Luxembourg, LU (26th September, 2022) – Jindal Films (Hall 7 Stand 545), a global leader in the development and manufacture of specialty films for the flexible packaging and labeling markets, will showcase at FachPack 2022 various print, barrier and sealing technologies designed to facilitate the switch from non-recyclable laminates (i.e. containing PET, Alu-foil, Paper …) towards mono-material mechanically recyclable PP based laminates for flexible packaging markets.

PET FILM REPLACEMENT

Facing numerous demanding packaging applications, improved heat resistant OPP films are being developed to address the recycling needs of the flex-pack industry with the removal of PET films. Jindal Films is launching a breakthrough technology with Bicor™ 12MB100, a very thin and very high stiffness OPP film for broad PET replacement applications to help brand-owners continue their packaging “light-weighting” journey while ensuring a robust print conversion.

For more specialized applications, Bicor™ 25MR100 is also being proposed for outer webs in retort-sterilized applications, to help minimize the shrinkage and visual distortion during the heat sealing and steam autoclave operations when designing PP-based retort laminates.

PAPER REPLACEMENT

Increasingly paper is being removed from flexible packaging when in lamination with polyolefin barrier and sealant films. Jindal Films is expanding its outer web non-heat sealable OPP films portfolio with a very low gloss finish (BICOR™ 18 & 25CSRM) to provide a matt-look traditional of Paper-based laminates.

ALU FOIL REPLACEMENT

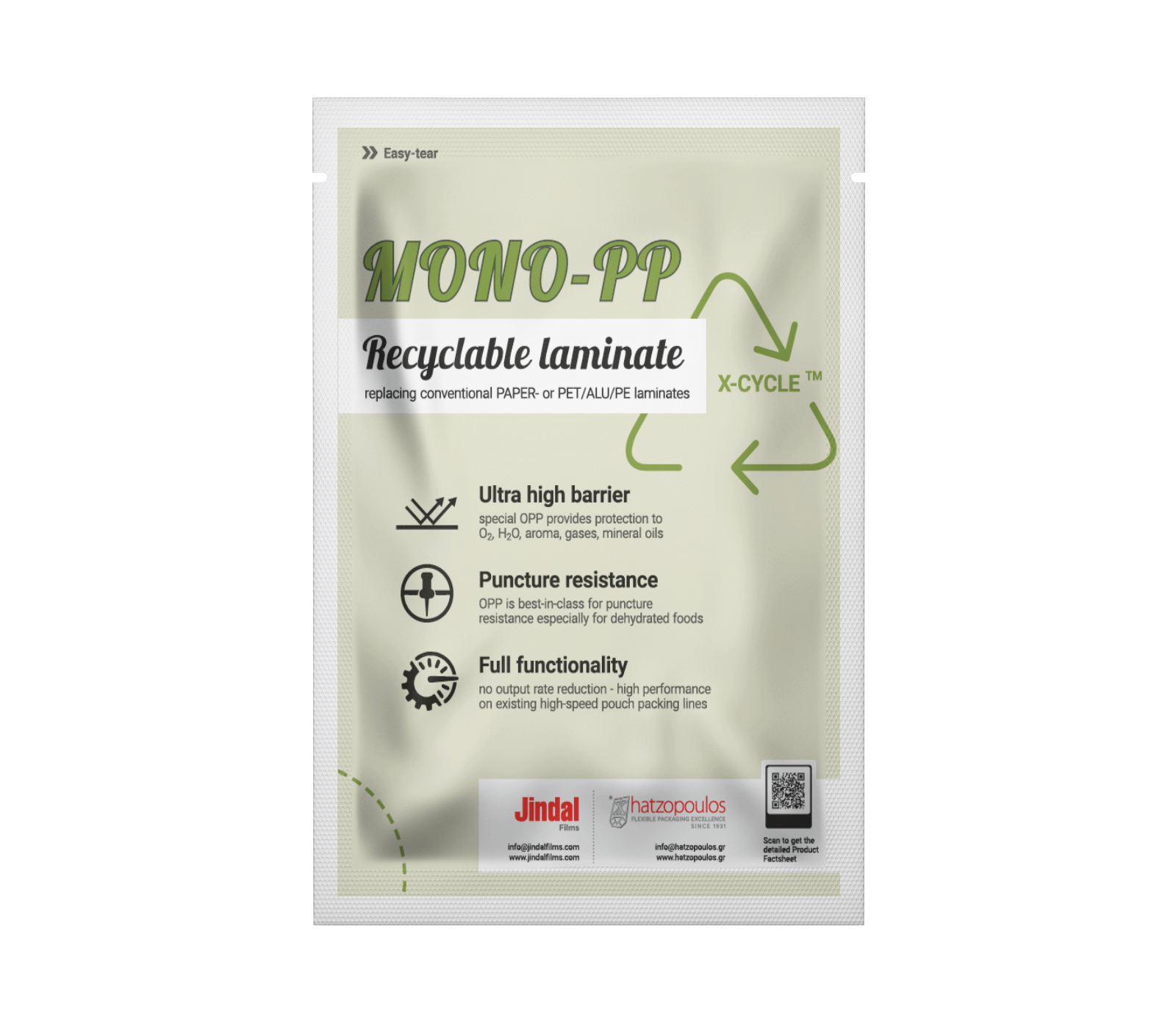

Jindal Films is expanding its broad range of barrier film solutions designed to replace traditional Aluminum foil by using modified barrier technologies on thin OPP films. Its highest barrier solution Metallyte™ 16MM883 is being increasingly used across Europe – from coffee markets to infant nutrition – to help brand-owners progressively shift their non-recyclable barrier laminates (e.g. PET/ALU/PE, Paper/ALU/PE) towards PP-based barrier laminates for recycling use in the current or developing PP or mixed-PO recycling streams.

PVDC REPLACEMENT

PVdC coated films are progressively being substituted with non-halogenated more recycle friendly solutions. Jindal Films is launching new BICOR™ 36&42 COS5 films with PVdC-free designs, specifically for the demanding Cosmetic overwrap market. This new range of high-gloss high-seal performance coated OPP films provide high scuff and perfume resistance for perfume or health & beauty aids applications.

LIVE DEMOS – PP MONO-MATERIAL SOLUTIONS FOR BARRIER POUCH & STAND-UP POUCHES

During FachPack 2022, two leading pouch machinery suppliers will be displaying all OPP-based barrier laminate solutions using Jindal Films’ film technologies:

1. SN Maschinenbau GmbH (Hall 1 stand 421) will run a flat pouch format on an FME20 high speed machine using a high barrier PP 3-ply laminate produced by A. Hatzopoulos S.A. (Hall 7 stand 313) based on Jindal Films’ Bicor CSRM, Metallyte MM883 and Bicor MB344US.

2. WOLF Verpackungsmaschinen GmbH (Hall 1 stand) will run a doy-pack format on a VFFS machine using a clear high barrier PP 3-ply laminate produced by VitraPack – a member of Korozo group (Hall 7 stand 322) – based on Jindal Films’ Bicor MB400, Alox-Lyte™ AO893 and Bicor MB344US.