Bicor™ AOH - Oriented Polypropylene Film

PRODUCT DATA SHEET

Product Description

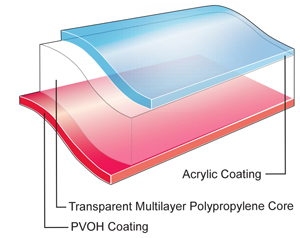

Bicor AOH is a two-side coated OPP film designed for high oxygen barrier laminations. AOH is designed to be used as the outer web in gas-flush applications for dry products.

Key Features

- Excellent optical properties, non-yellowing

- Breakthrough barrier performance

- Outstanding oxygen barrier

- Outstanding flavor and aroma barrier

- PVOH surface is receptive to water-based or solvent based inks and adhesives

- Requires priming for extrusion laminations

Properties & Typical Values

| Properties | Unit | 84 AOH | Test Method |

|---|---|---|---|

| Yield | in²/lb | 35600 | ITM 01 |

| Unit Weight | lb/ream | 12.1 | ITM 01 |

| Film Thickness | mil | 0.84 | ITM 02 |

| Gloss (45°) - Acrylic Surface | 95 | ITM 14 | |

| Haze | % | 1.0 | ITM 06 |

| Tensile Strength at Break - MD|TD 20 in/min pull rate, 2.0 in jaw separation | psi | 17500|32500 | ITM 50 |

| Dimensional Stability - MD|TD | % | -4.5|-4.0 | ITM 37 |

| Coefficient of Friction - Acrylic/Acrylic | 0.25 | ITM 20 | |

| Water Vapor Transmission Rate - 100°F, 90% RH | g/100 in²/24 hr | 0.37 | ITM 46 |

| Oxygen Transmission Rate - 73°F, 0% RH | cm³/100 in²/24 hr | 0.020 | ITM 42 |

Typical values should not be construed as finished product specifications (FPS).

Market Segments

- Crisps and Snacks

Applications

- VFFS Flexible Packaging

Processing Method

- Inner Web Adhesive Lamination

- Outer Web Adhesive Lamination

- Solvent Flexographic Printing

- Solvent Rotogravure Printing

- Water-based Flexographic Printing

- Outer Web Extrusion Lamination

Food Contact

Any further regulatory information on this product (i.e. Food Contact application, Presence/absence of substances, Reach, …) are accessible on the below link: http://www.jindalfilms.com/login-register-docmg/

© 2024 Jindal Films. Jindal Films. Jindal Films, the Jindal Films’ logo, and other product or service names used herein are trademarks of Jindal Films, unless indicated otherwise. You may not upload, display, publish, license, post, point to, frame, transmit or distribute either this document or its information, whether in whole or in part, without Jindal Films’ prior written authorization. To the extent Jindal Films provides prior written authorization, the user may use the document or its information only if the document is unaltered and complete, including all of its headers, footers, disclaimers and other information. Any data included herein may be based upon: analyses of representative samples and not the actual product shipped, typical values, or otherwise. The information in this document relates only to the named product or materials when not in combination with any other product or materials. We base the information on data believed to be reliable, but we do not represent, warrant, or otherwise guarantee the accuracy, reliability, or completeness of this information; nor do we warrant, expressly or impliedly, the merchantability, fitness for a particular purpose, freedom from patent infringement, or suitability of the products, materials or processes described. The user is solely responsible for all determinations regarding any use of material or product and any process in its territories of interest. We expressly disclaim liability for any loss, damage or injury directly or indirectly suffered or incurred as a result of, or related to, anyone using or relying on any of the information in this document. This document is not an endorsement of any non-Jindal Films’ product or process, and we expressly disclaim any contrary implication. The terms “we,” “our,” “Jindal Films” and “Jindal” are each used for convenience, and may include Films Americas LLC, Jindal Films Americas LLC, Films Europe S.ár.l., Jindal Films Virton SPRL, Jindal Films India Ltd., or any companies affiliated with them in the production and sale of film products. There are a number of such affiliated companies, some with names including “Jindal” or “Films” and some not. Neither these terms and conditions, nor anything else in this document, is intended to override or supersede the legal separateness of those affiliated companies and responsibility for local action and accountability remains with them.