Metallyte™ UBWES - Oriented Polypropylene Film

Product Description

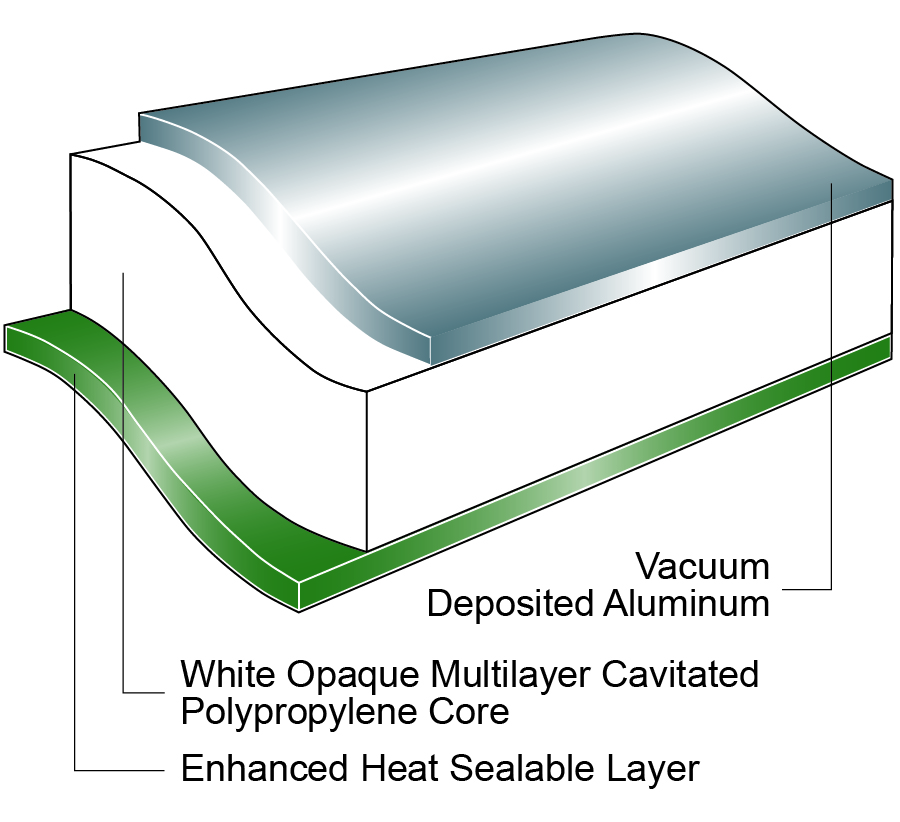

MetallyteTM UBWES is a multi-layer, cavitated, white OPP film with an enhanced sealant to allow sealing through contamination. This film has an exceptional barrier to gases, flavors, and moisture. It is metallized on one side with a proprietary sealant layer on the other. UBWES is lap sealable to other coextruded OPP films.

UBWES is used as the inner web for adhesive and extrusion laminations, where superior moisture and oxygen barriers are required. UBWES provides an excellent light barrier and is designed to provide strong, leak-free seals for flat pouches and has been designed specifically to replace foil and a sealant web in those applications.

Key Features

- Exceptional seal strength

- Outstanding opacity

- Outstanding moisture and oxygen barrier

- Excellent aroma and flavor barrier

- Excellent flex-crack resistance

- Excellent hot tack

- Improved barrier to Mineral Oils compared to non-barrier film(1)

- Significant mineral oils contamination protection period of more than 2 years

Properties & Typical Values

| Properties | Unit | 28UBWES | Test Method |

|---|---|---|---|

| Yield | m²/kg | 48.4 | ITM 01 |

| Unit Weight | g/m² | 20.7 | ITM 01 |

| Film Thickness | µm | 28 | ITM 02 |

| Optical Density | 3.0 | ITM 11 | |

| Dimensional Stability 135°C / 275°F, 7 min - MD|TD | % | -5.0|-3.0 | ITM 37 |

| Minimum Sealing Temperature (Min 750g/25mm) - 25N/cm2 - 0,5 sec - Flat/Flat enhanced seal/enhanced seal | °C | 71 | ITM 26 |

| Heat Seal Range (RDM) RDM – 750gr – single web – 25N/cm² – 0.5sec – flat/flat | °C | 79 | ITM 26 |

| Water Vapor Transmission Rate - 38°C, 90% RH | g/m²/24 hr | 0.1 | ITM 46 |

| Oxygen Transmission Rate - 23°C, 0% RH | cm³/m²/24 hr | 0.1 | ITM 42 |

Market Segments

- Biscuits/Cookie/Crackers

- Dry Foods and Beverage Powders

- Pet Food

- Chips and Snacks

Applications

- HFFS Flexible Packaging

- Pre-made Bags - Flexible Packaging

- VFFS Flexible Packaging

- Pouches - Flexible Packaging

- Flat Sachet

Processing Method

- Inner Web Adhesive Lamination

- Solvent Flexographic Printing

- Solvent Rotogravure Printing

- Inner Web Extrusion Lamination

Food Contact

Any further regulatory information on this product (i.e. Food Contact application, Presence/absence of substances, Reach, …) are accessible on the below link: http://www.jindalfilms.com/login-register-docmg/